Steam Turbine Manufacture

Since 2005 the cooperation between NTP and BPPT (Agency for Assesment and Application of Technology) supported by Department of Industry and Commerce the Republic of Indonesia (RI) has been successful in the manufacturing and developing of steam turbines with capacities from 450HP to 4MW then we are constantly risen achieve a capacity 7 MW.

Steam Turbine Specialist

With our team experience and expertise we have capabilities to repair and develop a lot of project such as:

Rotating Parts:

- Blade Recondition

- Burnishing

- Dynamic Balancing

- Journal Area Repair

- Over Speed Device

- Probe Area Repair

- Re-blending

- Seal Area Repair

- Shaft Replacement

- Straightening

- Stubing

- Casing Repair

- Bearing Housing Repair

- Labyrinth Seal Repair

- Nozzle Repair

- Rebabbit Bearing

- Alignment

- Assesment

- Assembly and Disassembly

- Bearing Replacement

- Cleaning

- Control System Check

- Cooling System Check

- Labyrinth Replacement

- Non Destructive Test

- Power Upgrade

- Relocation

- Start-Up and Commisioning

- Vibration Diagnostic

- Blade

- Diaphragm

- Disk

- Labyrinth

- Nozzle

- Shaft

- CMM (Coordinate Measuring Machine)

- Composition Test

- Dimensional

- Dynamic Balanching

- Electrical Run Out

- FPI (Flourecent Penetrant Inspection)

- Hydro Static Test

- Over Speed Device Test

- Photo Scanning

- UT (Ultra Sonic Test)

- Assembly and Disassembly

- Chemical Cleaning

- Heat Treatment

- Jig Boring Machine

- Mechanical Cleaning

- Plating

- Thermal Spray

- Vertical Lathe Machine

- Welding

- Blohm and Vos

- Dresser Rand

- Fuji Electric

- KKK

- Nadroski

- Peter Brotherhood

- Siemens

- Shinko

- SNM

- Terry

- Gas Turbine

- Centrifugal Compressor

- Pump

- Steam Turbine

- Turbo Charger

Special Program

We realize that sometimes you need special services to meet your industrial turbine needs to always be in top performance, therefore we have special services including training services and field services

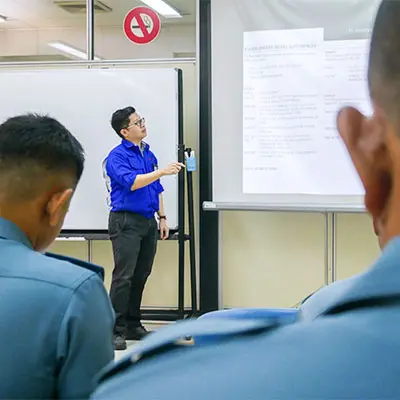

Human Resource Training

We, at NTP consider out people as our most valuable assets, therefore we intentionally establish our shopisticated facilities to fully support our efforts to enhance our people's skills and performance. We organize regular training programs that cover skill and knowledge improvements. These training programs are formally acknowledge by a number of the world's best rotating equipment manufacturers. We also grant scholarship programs called "The Industrial Apprentice Training". Successful candidates who passed the selection will undergo intensive learning, with all costs and expenses fully covered by NTP.

Field Service

Rotating equipment constitutes the critical component in all industrial fields. NTP of which business focuses in the rotating equipment repair has formed a task force to perform the field service.

Support Facilities

- Engine Control/Accesories Repair & Overhaul

- Engine/Module Stripping & Rebuilding

- Engine Testing

- Rotor Balancing

- Bearing Analyzer

- Boroscope

- Coordinate Measuring Machine

- Eddy Current

- Electrical Runout

- Fluorescent Penetran

- Magnetic Particle

- Over Speed Trip Device

- Radioraphy

- Visual & precise Dimension

- Painting

- Wire Spray (Sprababbit, Sprabronze, Stainless Steel)

- Termo Spray (Ni Graphite, Ni Ai)

- Plasma Spray (chromonium carbide, tungsten carbide, cobalt, polyester)

- Electro Plating (copper, nickel, hard chrome, silver, tin, cadmium, black oxide)

- Selectron Plating

- Shot Peening

- Hydrogen Furnance

- Vacuum Furnace

- Local Age

- Chemical Cleaning

- Mechanical Cleaning

- Ultrasonic Cleaning

- Boring

- Electrical Discharge Machine

- Grinding

- Lathe

- Milling

- Conventional Machining

- Electric Discharging Machine

- CNC Lathe

- Brazing

- MIG Welding

- Tig Welding

- Spot Welding

- Dabber Welding

Heavy Duty Industrial Coating

Coating was developed primarily to provide antifouling and corrosion protection to driven compressor components and industrial gas turbine components and industrial gas turbine components exposed to wet chloride attack , as well as steam turbine components.

with personnel who are experts in their fields and official certification from OEM, we can help you solve your foulling and corrosion problems by using high-quality coatings, such as:

SermeTel® coating consists of alumunium-filled chromate/phoshphate basecoat, sealed with a chemically inert chromate phosphate topcoat.

The coating provides excellnt protection to stainless steel and ferrous alloys,and will operate at temperatures up to1200°F (650°C)

SermeTel® coating types :

- SermeTel® 5380 DP

- SermeTel® 5380 OS

- SermeTel® 6F-1

- SermeTel® 2F-1

SermaLon® coating system was developed primarily to provide antifouling and corrosion protection to driven compressor components and industrial gas turbine components and industrial gas turbine components exposed to wet chloride attack , as well as steam turbine components

The SermaLon® coating system consists of :

- An aluminum-filled chromate/phosphate bond coat

- An intermediate high temperature polymeric inhibitive coating

- A PTFE-impregnated topcoat that provides a barrier against corrosion and excellent resistance to fouling